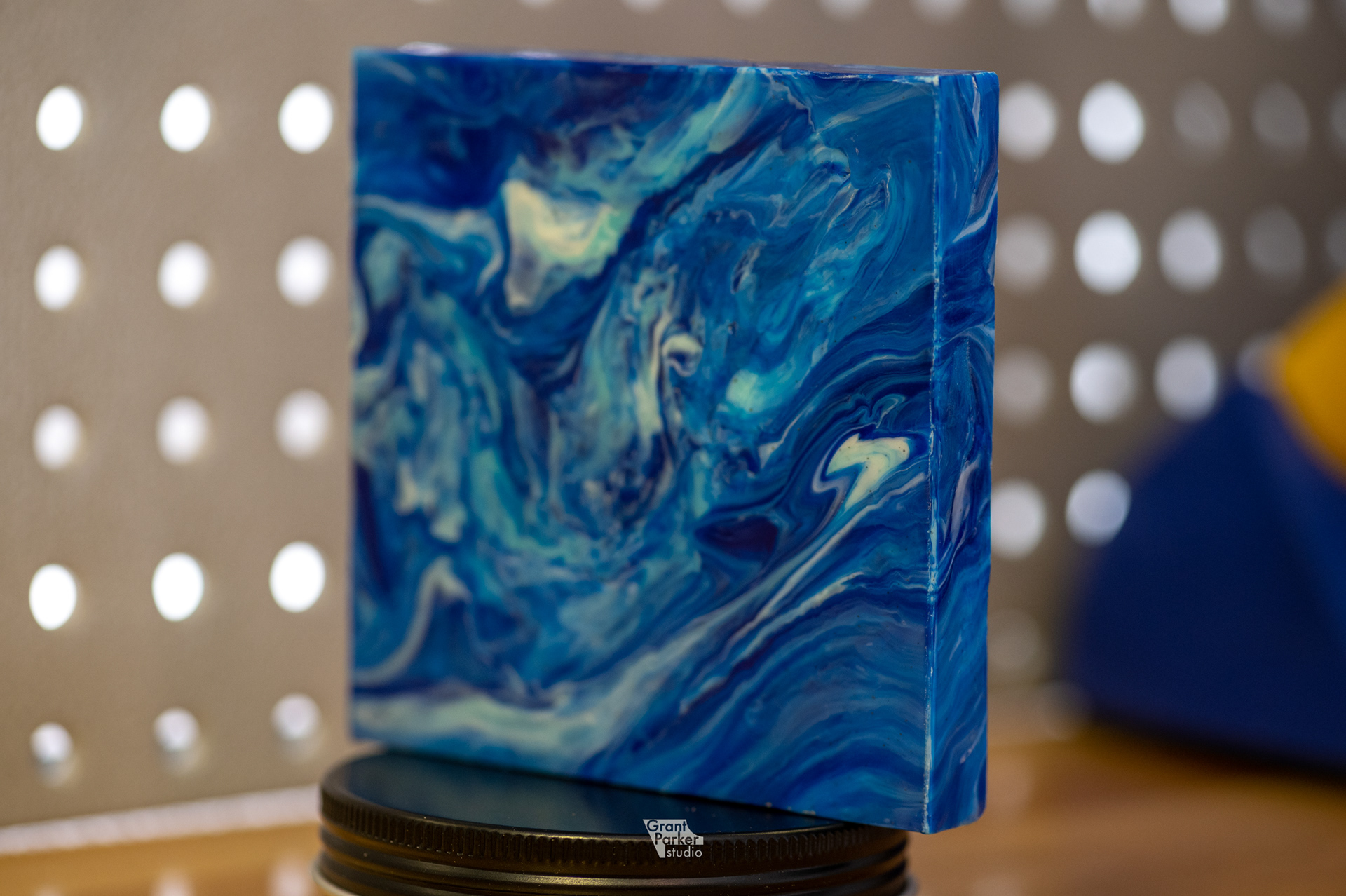

What a beauty.

My favorite melt to date. The colors meshed really well. With this one I twisted and folded the melted plastic more than previous melts. This helped with removing air bubbles and blending the plastics together. I finished the steel top plate this time and was able to heat all the surfaces that are in contact with the plastic. This addition turned out great and made all the surfaces smooth and shiny without sanding or extra heating as post processing. There are a few imperfections but nothing like my last pieces.

Post processing

I used a chisel and small hand plane to remove the excess squeeze out that occurred. I also beveled the edges a bit so that the corners are not as harsh. No sanding or heating was done on this one.

Learnings from this round

I worked and twisted the mass into a large clump that cooled too much in the process. I placed it back in the oven but did not have the temp high enough to keep it in a liquid state. The outside was still warm but the core had cooled. After I gave it some time I eventually had to take it out of the oven and rip it into smaller pieces that were able to melt through again.

For next time

Twisting and folding the plastic but trying to keep it flat to continue to heat evenly.

Run the oven a bit hotter to counter loosing heat when twisting.

Run the same mold no new modifications.

A note on why I am doing this.

The goal of these experiments is to find and document ways to and not to recycle plastics with useable results.

I am working with the space and tools I have. I realize that this project would go smoother with all metal molds and a plastic shredder. Eventually I may get those kinds of tools but for now, I will continue to make do with what I have.

Reach out on my contact page if you are up to collaborate or have any thoughts to share. Thanks for reading and good luck with what you create!